-40%

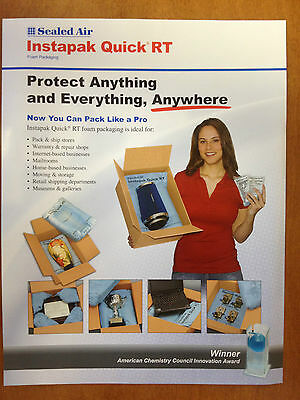

Instapak Quick RT #10 - 36 Bags 15 X 18"

$ 92.39

- Description

- Size Guide

Description

Instapak Quick RT #1036 - Bags 15 X 18"

Instapak Quick

®

RT

(Room Temperature) Foam Packaging

Innovative, Highly Protective Packaging With No Start-Up Costs

Instapak Quick

®

RT Packaging: All the cost-saving benefits and proven performance of Instapak Foam Packaging without the need for equipment.

Easy-to-Use:

Anyone can become a packaging expert - instantly

Superior Product Protection:

Virtually eliminate shipping damage

No Start Up Costs:

No dispensing system or warming unit needed

Versatile:

Protects products of almost any size, shape and weight

Fast:

Expands in seconds to form custom-fit protective foam cushions cushions

Convenient:

Takes up little space and is completely mobile so you can use it anywhere

Customer Satisfaction:

Product arrives in a neat professional package

The Right Instapak Quick

®

Product for Your Application

Quick

®

RT

provides general duty cushioning and light blocking and bracing for products of all different sizes and weights. It is designed to work across a wide range of applications. For heavier products,

Quick Tuff

®

RT

offers the maximum protection and expands the versatility while enhancing the performance of the Quick

®

packaging process.

How

Instapak Quick

®

RT

Foam Packaging Works

Instapak Quick

®

RT protective foam packaging can be activated right out of the box and requires no additional equipment.

Press!

Press hard on the component "A" oval to break seal.

Pat!

Alternately "pat" back and forth on the "A" and "B" ovals fifteen to twenty times.

Pack!

Nestle the product into the rising foam. Repeat the process as needed.

Determine If

Instapak Quick

®

RT

Foam Packaging is Right for You

Which Foam Do I Need?

Instapak Quick

®

RT is used to protect products of various size, shape and weight. To determine which Instapak Quick

®

RT packaging foam is best suited for your product, refer to the chart below.

You will need to know two attributes of your product:

Product weight

Area - in square inches - of the smallest side of the product

Example:

Your product is 13 inches wide x 10 inches long x 5 inches high and weighs 10 pounds. The smallest side is 10 x 5 = 50 square inches. Using the chart, you find that Instapak Quick

®

RT is the right foam to protect your product. If the same size product weighs 25 pounds, Instapak Quick Tuff

®

RT foam should be used instead.

*For Rugged Products - those classified as "Not Fragile" - Instapak Quick

®

RT foam should provide adequate protection.

Please Note:

The shipping and transportation environment is a very unpredictable chain of events. Packaging is not an exact science, thus we caution that the chart above be used as a guide and not a final stamp of approval of guarantee that Instapak Quick

®

RT foam will or will not be successful in protecting your product. You should test the application to determine the suitablilty of Instapak Quick

®

RT foam packaging for the intended use.

Product & Safety Information for

Instapak Quick

®

RT

Foam Packaging

This product contains two separate liquids (Component "A" and Component "B"), that when combined and mixed together, will react and expand to form polyurethane foam.

Please note:

Instapak Quick

®

RT is for industrial use only.

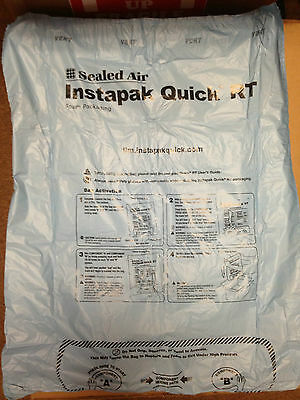

Instapak Quick

®

Product

Bag Color:

MSDS* (PDF):

Instapak Quick

®

RT

Blue

Instapak Quick Tuff

®

RT

White

Instapak Quick

®

Silver

*The information contained in the MSDS’s applies to the liquid components and not the resulting foam.

Chemical Characteristics

Storage Temperature:

Usage Temperature:

Instapak Quick

®

RT & Quick Tuff

®

RT

50-100° F

65-90° F

Instapak Quick

®

50-100° F

Quick

®

Warmer temperature

Foam Typical Performance Characterisitcs

Rise time

Free rise core density*

Bag surface temperature

Instapak Quick

®

RT

15-20 seconds

nominal 0.55 lb/ft

3

145-170° F

Instapak Quick Tuff

®

RT

25-35 seconds

nominal 1.1 lb/ft

3

140-165° F

Instapak Quick

®

15-20 seconds

nominal 0.4 lb/ft

3

130-155° F

*In-Use Density: The density of foam obtained when rise is restricted is always higher than the free rise density for all commercial packaging foams. It is typically 1.5 to 2.0 times the free rise density.

Expanded Foam

Instapak Quick

®

RT components "A" and "B" are mixed inside an internal pouch. The material that expands is liquid polyurethane. This liquid quickly expands and solidifies to form a custom-fit protective packaging material for your product. Polyurethane foams are chemically inert and not considered hazardous materials. In fact, they are found in many aspects of our daily lives, e.g., bedding, chair cushions, carpet padding and automobiles.

The packaging area should be designated as a "no smoking" area. Smoking in the presence of polyurethane foams, as with most packaging materials, increases the risk of fire.

*****************************************************************************************************************************************************************************

We're an authorized dealer for

Sealed Air

and you can contact us with any questions:

Hexa Packaging Supplies